Calibrate Pressure Gauge

A pressure gauge sensor plays a crucial role in monitoring and measuring the pressure within the brake system. This ensures the braking system operates safely and effectively. Additionally, it can be used to measure the pressure in oil tankers during the extraction process, facilitating smooth and efficient operations.

The system enables precise calibration of the pressure gauge sensor and provides analytics through interactive widgets, graphs, and reports to quickly indicate whether pressure is within a safe range or in a critical zone, facilitating timely intervention.

To Get Started

- Login to your account

- Go to Settings > General > Object

- Double-click on the object record for which you want to calibrate the sensor.

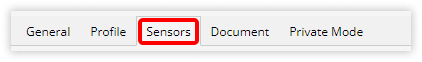

- Navigate to Sensor.

To Calibrate Sensor

- Activate the connection type by clicking on the checkbox given in the Active column.

- Click on the drop-down of Connected Sensor and select Pressure Gauge.

-1.png?width=688&height=82&name=Frame%20667%20(5)-1.png)

- Click on the Calibration

button. A new window will appear.

button. A new window will appear.-1.png?width=688&height=297&name=Frame%20667%20(7)-1.png)

- Select the Sensor Output Unit, which is set to Millivolt by default, as the system will capture Pressure Gauge values in millivolts (mV) from the specified port.

- Pressure Unit : The system will convert the incoming Pressure Gauge values from mV to the selected pressure unit, which is BAR, PSI, or KG/CM2.

- Enter the Multiplication Factor, a unit correction value that adjusts raw data by multiplying it. This factor is determined based on the specific behavior of the device.

A Multiplication Factor is a value applied to adjust raw data to its correct unit. It varies depending on the device and ensures accurate measurements by standardizing the unit.

-

- To ensure accurate calibration, please activate the Consider Stop checkbox. This will allow the system to include pressure gauge values recorded when the vehicle is in a stopped condition in the calibration calculations.

- Safe Pressure Levels: Define the acceptable pressure range required for safe and optimal operation.

- Warning Levels: Set thresholds to indicate users when the pressure approaches unsafe levels, indicating potential issues.

- Critical Levels: Specify pressure limits that indicate dangerous conditions, requiring immediate action to prevent system failure.

- Apply To: This feature allows you to replicate the same pressure guage calibration settings across different devices or vehicles, streamlining the configuration process.

- When you click on "Apply To," a dropdown menu will appear, allowing you to select the specific object to which you wish to apply the same calibration settings.

.png?width=424&height=81&name=Frame%20667%20(13).png)

- When you click on "Apply To," a dropdown menu will appear, allowing you to select the specific object to which you wish to apply the same calibration settings.

- Download a sample file and define the voltage range by entering values in the 'Voltage From' and 'Voltage To' columns along with the corresponding pressure readings for each specified range. Once you have completed this, upload the calibration file using the Upload File option.

- Click on the Save 💾 icon on the calibration window to save the entire configuration.